Summary

When connecting legacy or new assets for IoT use cases, you are faced with a variety of options: which sensors and gateways to use, wired vs. wireless networking, battery life for sensors and gateways, which communication protocols to use, how to collect data, what functionality needs to reside at the edge (analytics, storage), device management - the choices are staggering. This session will discuss best practices for this critical first step in IoT deployments.

KEY TAKEAWAY 1: Understand the decision criteria for sensor selection as you develop your Industrial IoT strategy

KEY TAKEAWAY 2: Learn about battery life, communication protocols, and edge storage in industrial IoT use cases

KEY TAKEAWAY 3: Deepen your knowledge of Edge analytics during data collection

The following is a summary of the Hands-on Lab "IIoT Sensor Deployment - What and How" at PI World 2018 in San Francisco, CA.

All products, names, trademarks and registered trademarks are property of the respective owners. All company, product and service names used in this document are for identification purposes only. Use of these names, trademarks, and brands does not imply endorsement.

The hands-on lab covers several use cases to illustrate the various options:

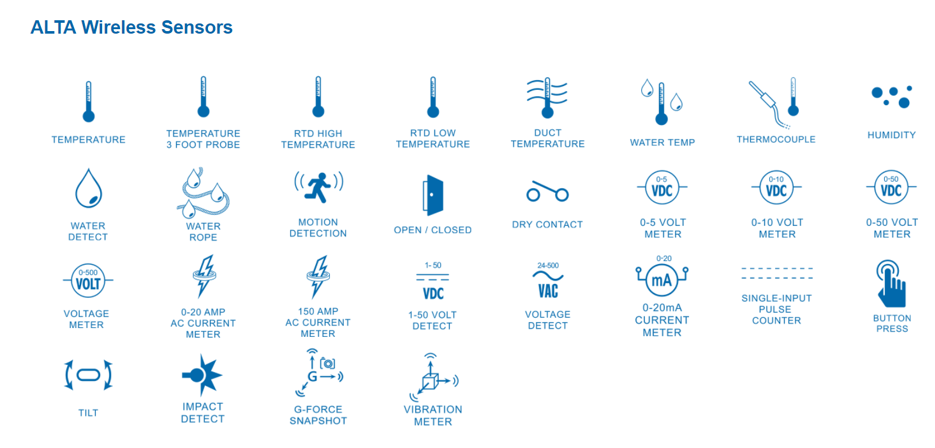

- Non-invasive sensor measurements – voltage, amps, pressure, process fluid temperature, process liquid flow, liquid level, vibration, thermography (IR temperature) etc.

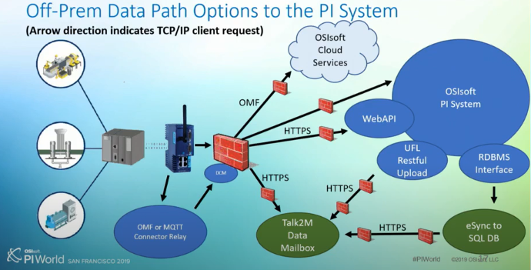

- Data flow via wireless communication - RF mesh network, WiFi, cellular etc.

- Data payloads via MQTT (Sparkplug B), Modbus IP, PI UFL http, OPC UA, Ethernet IP, HART-IP etc.

All examples use currently shipping or soon to be released PI System software.

The lab does not require any coding or developer related skills.

Use Case 1: Energy usage – Amps (current transformer) – Advantech

In this Exercise, you collect current (amperage) usage readings; these measurements are used to track energy consumption, unbalanced three phase loads etc.

Energy monitoring starer kit: http://www.advantech.com/products/a0af34d2-a0dd-42d9-b323-82e65581bf8f/bb-wsk-nrg-2/mod_de06dc19-f51a-441f-b23d-604777fb…

http://advantech-bb.com/product-technology/iot-and-network-edge-platforms/smartswarm-341/

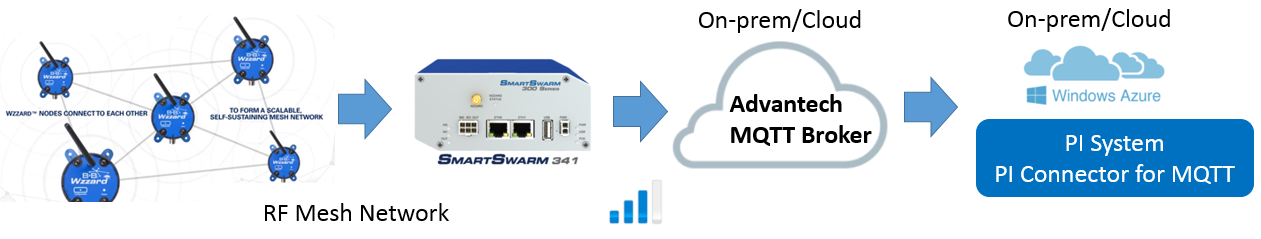

Edge wireless sensor (5 year battery) uses RF mesh network to transmit to an IoT Gateway (includes support for cellular) which publishes to MQTT broker; and then is written to PI using PI Connector for MQTT (Sparkplug B)

The Smart Swarm box includes Node-RED

Use Case 2: Condition monitoring – Motor Temperature (thermal camera) – Fluke

In this Exercise, you collect temperature readings using a thermal camera.

For more information on thermography use cases, see http://www.maintworld.com/Applications/IR-Thermography-in-Maintenance

http://en-us.fluke.com/products/infrared-cameras/fluke-ti400-infrared-camera.html

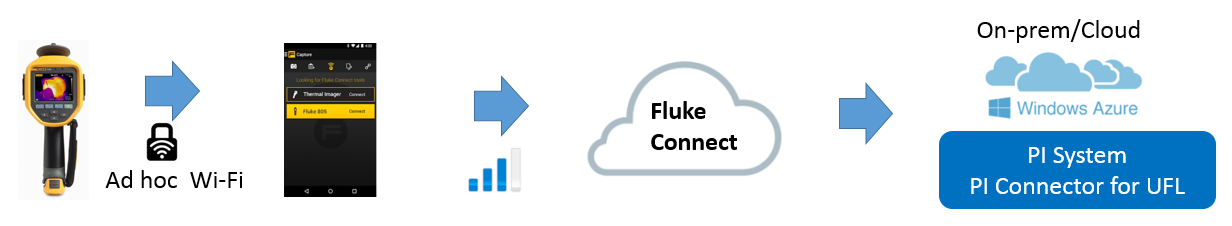

Handheld thermal camera uses ad hoc WiFi to connect to a smart phone, then via cellular to transmit to Fluke Connect cloud, and then the temperature readings (no thermal images) are written to PI using PI Connector for UFL (https)

Use Case 3: Condition monitoring – Vibration - National Instruments and Allied Reliability

In this Exercise, you collect and compare vibration readings for a balanced/unbalanced motor. Condition monitoring via vibration accelerometers is widely used for CbM (condition based maintenance) and fault diagnostics.

http://www.ni.com/insightcm/http://www.ni.com/insightcm/

Interfacing with the OSIsoft PI System Software - InsightCM 3.7 Manual - National Instruments

https://alliedreliability.com/

http://www.ni.com/en-us/support/model.crio-9037.html

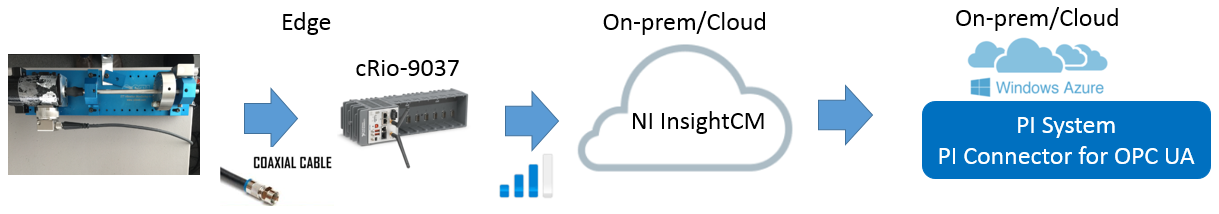

Vibration accelerometer (continuous ) with high sampling rate (20 kHz) is edge-processed ( including FFT - Fast Fourier Transform) to extract key features (RMS, peak, crest etc. including speficified spectral data - 1x, 2x, 20x, 47x etc.) and sent to NI InsightCM; then it is written to PI via PI Connector for OPC-UA

Reference installation: Duke Energy http://landing.ni.com/dukeenergyiiot

Use Case 4: Process fluid temperature – Emerson

In this Exercise, you collect the temperature of a process fluid flowing inside a pipe using non-intrusive pipe clamp based sensors.

https://www.emerson.com/en-us/catalog/rosemount-648-wireless-temperature-transmitter

http://www2.emersonprocess.com/siteadmincenter/pm%20rosemount%20documents/00813-0100-4952.pdf

https://www.emerson.com/en-us/catalog/emerson-1410-wireless-gateway

Wireless HART-IP device data is written to PI via PI Connector for HART-IP

Other HART-IP based devices - Emerson acoustic sensors – steam traps: Steam Traps | Emerson US

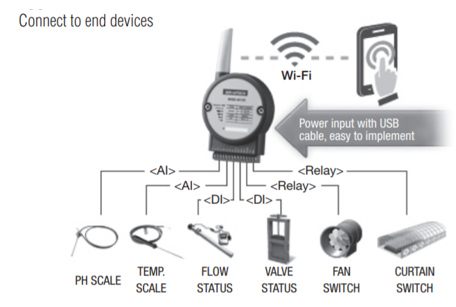

Use Case 5: Any 4-20 mA or 0-10 V sensor – Advantech

In this Exercise, you collect pressure readings. Note that the edge device (WISE 4012E) can be solar powered.

Any analog/digital sensor (4-20 mA or 0-10 V) measurement is written to PI via Modbus IP

Use Case 6: Liquid level – Keyence

In this Exercise, you collect liquid level readings. The benefits of a non-contact sensor (radar level transmitter) are detailed at:

https://www.keyence.com/products/process/level/fl/index.jsp

Any analog/digital sensor (4-20 mA or 0-10 V) measurement is written to PI via Modbus IP

Other links:

PI World 2018 IoT Hands-on Lab Manual - See in the Comment section.

Fluke

https://www.fluke.com/en-us/product/condition-monitoring/vibration/3561-vibration-sensor

Corrosion monitoring

Remote non-intrusive corrosion monitoring

Monnit industrial wireless sensors

ABB wireless HART IP vibration sensor

WiMon vibration and temperature sensor | ABB

Steam traps

Monitoring Steam Traps with the PI System

Ultrasound monitoring

Bearing Condition & Lubrication Monitoring https://www.uesystems.com/product/ultra-trak-750/

FLIR thermal imaging

FLIR AX8 thermal/visual camera - w/support for Modbus/TCP and Ethernet/IP

https://www.flir.com/instruments/utilities/electric-power-generation/

Digitize and wireless enable old analog gauges

Supports BACnet and OPC

http://www.cypressenvirosystems.com/video/wireless-gauge-reader/wireless-gauge-reader-demo/

SKF vibration and oil analysis

HMS Ewon Flexy

Push Data to the OSIsoft PI System with HMS Industrial Networks

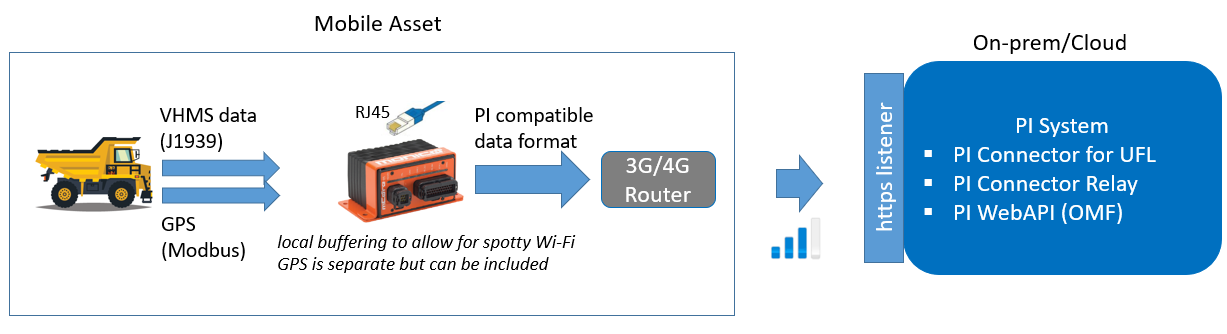

Monico mCore SDR for mobile assets (heavy trucks etc. ...)

https://www.monicoinc.com/mcore-sdr

Newer LoRaWAN Sensors and Gateways

Sensors and Gateways with built-in support for LoRaWAN is an option for situations where your plant-floor does not have WiFi/5G at all or is WiFi/5G bandwidth constrained.

Other OSIsoft links

Industrial IoT Solutions | OSIsoft

IoT Strategies and Tactics for Connecting Legacy Assets

See attached PDF below for the slides from PTC LiveWorx18 presentation