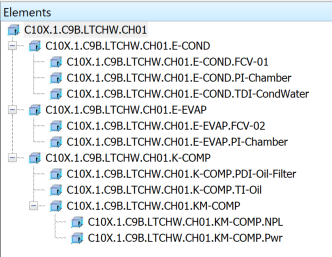

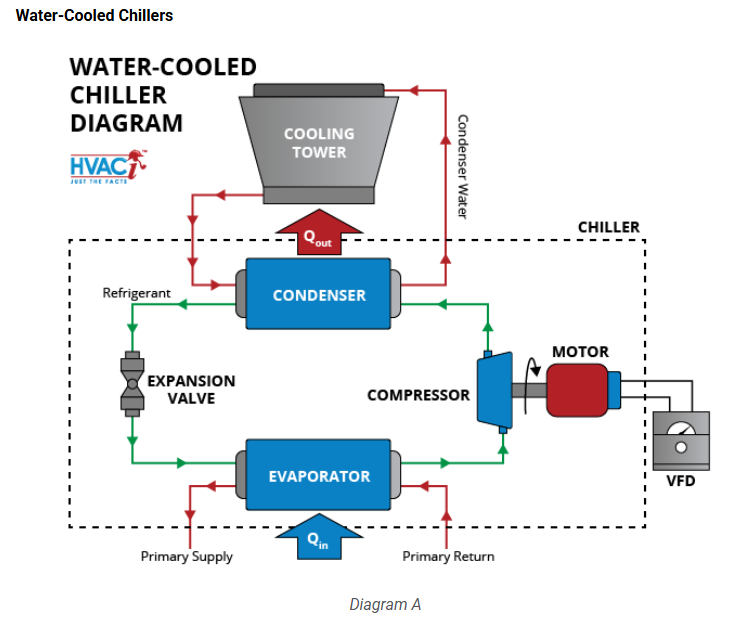

Shown Below is a Chiller model in PI for a lightly monitored unit typical in Facilities or Transportation. The PIDT model of Chillers encourages a composition of multiple assets that combine to form a chiller: heat exchangers, compressor(s), Motors, piping and valves. You assemble your chiller in PI using the PIDT libraries for BAS, HEX, CPR, MTR, VLV, PIP.

Typically, chillers in Facilities don't justify a lot of expense for monitoring. They are lightly instrumented as shown in the example Chiller PI model below. Standalone sensors are common. They loosely catch a shift or erratic deviation from norm. The strategy relies on experienced first responders to inspect, take more measurements and troubleshoot. It is low init cost and low admin but requires skilled ops. The strategy relies on early indications of the problems so that there is time to research and reverse the issue before any outage happens.

Like everything, a chiller asset can vary widely based on its employer. Chillers in more critical service can justify the expense of maintaining more sensors. The intent of adding sensors is to provide more direct diagnosis of the root cause. Faster responses, less reliance on SME troubleshooting. This combined with even earlier detection of anomalies is what you hope to gain from investing in more sensors. Ultimately, your investments achieve a higher reliability. This allows you to run closer to Maximum Capacity w/o failure and reduces unplanned surprise outages.

Additional sensors for chillers might include these pursuits among others:

Compressor Wear (Effcy Calc, Temp In/Out, FlowRate, Press In/Out, Power Consumption)

Compressor Bearing failures (Vibration, Temp)

Heat Exchanger Fouled/Contaminated/WrongSize (Temp In/Out, FlowRate)

Motor Windings/Insulation (Temp)

Motor Bearing Failures (Vibration, Temp)